RPS Tracker is transforming load-and-haul earthworks for Civil Construction, Mining, & Environmental Remediation projects with Earthmoving Intelligence™.

Countless hours are lost to inefficient data collection, manual log sheets, and inaccurate project tracking numbers. Not to mention scrambling to Email & SMS daily shift summaries.

These methods result in wasted time, missed opportunities for optimizing organizational processes, and decreased profitability.

The outcome leaves gaps in your data and fails to provide complete visibility into what’s really driving the numbers – not allowing you to see what’s happening with your machines and operators.

Everyone tries to track active machines. But what about machines assigned to your project that aren’t active?

*Note: Excavator ‘movement’ includes both rotation and lat/long travel.

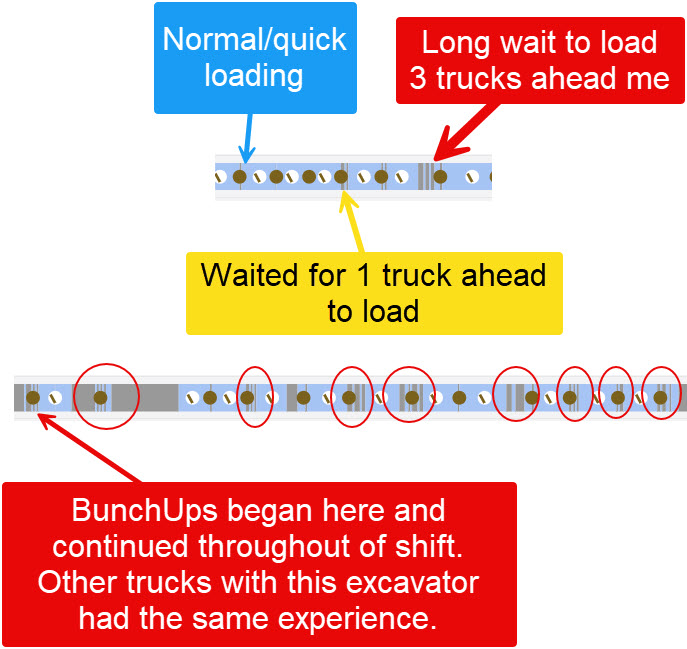

When something goes wrong or doesn’t add up, RPS Tracker gives you the full story.

In this real example, the driver from Truck 1 claimed, “A truck pulled out in front of me.”

With precise timing, RPS Tracker pinpointed and identified the exact moment and truck that crossed its path.

Audit ‘Critical Events’ and provide data-backed evidence for internal investigations, insurance claims, and legal proceedings.

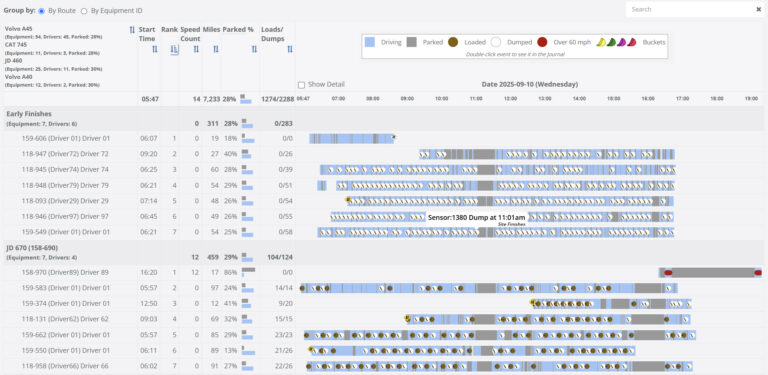

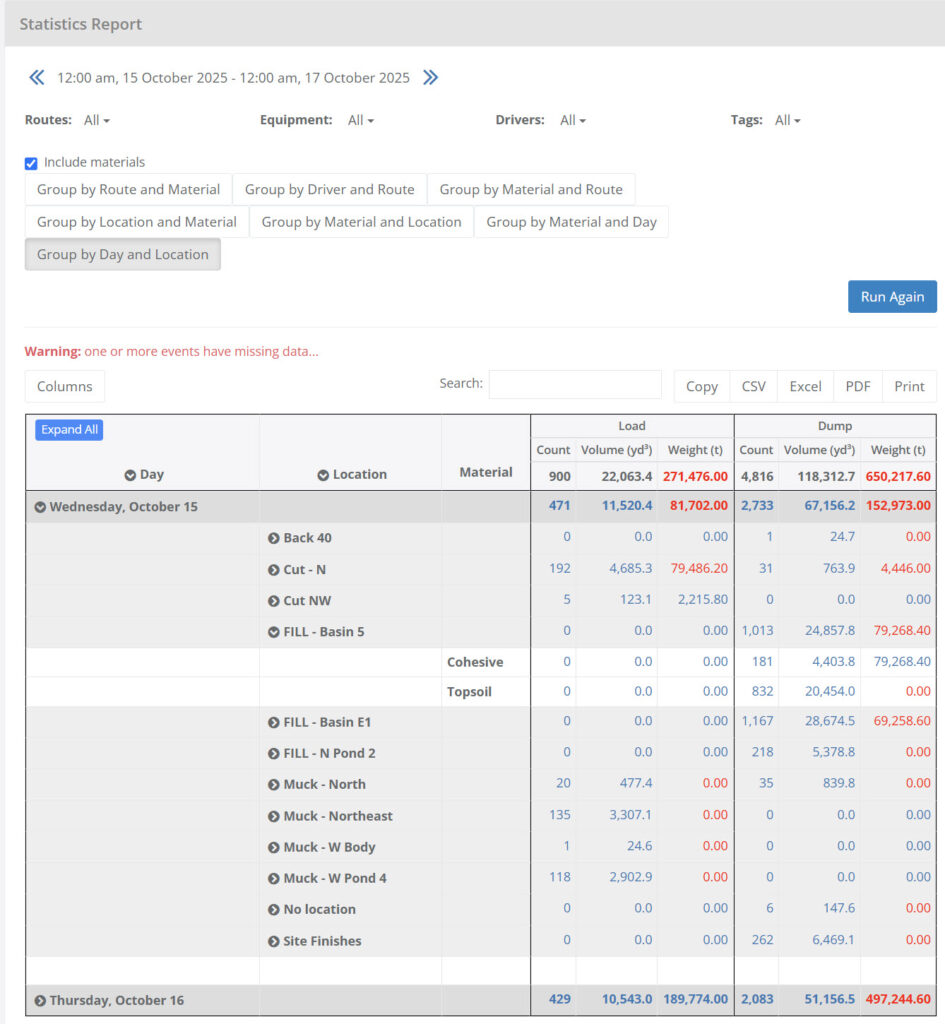

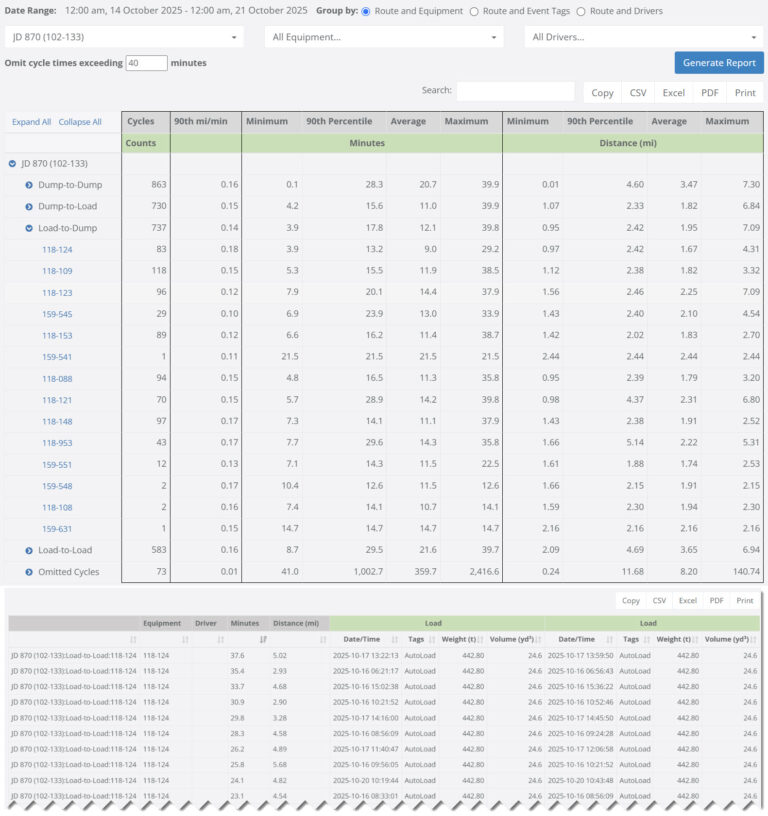

Details matter, but the real story comes from summaries you can trust and insights you can act on to stay profitable.

Easily organize your data to compare results, find patterns, compare performance, and uncover inefficiency and waste trends fast.

RPS Tracker allows you to easily group and sub-group your load and dump counts/volumes by day, location, material type(s), and more to benefit your project stakeholders, along with any other specific reporting needs.

Export summaries to CSV, Excel, PDF, Print, or the Clipboard for further analysis in your favorite tools.

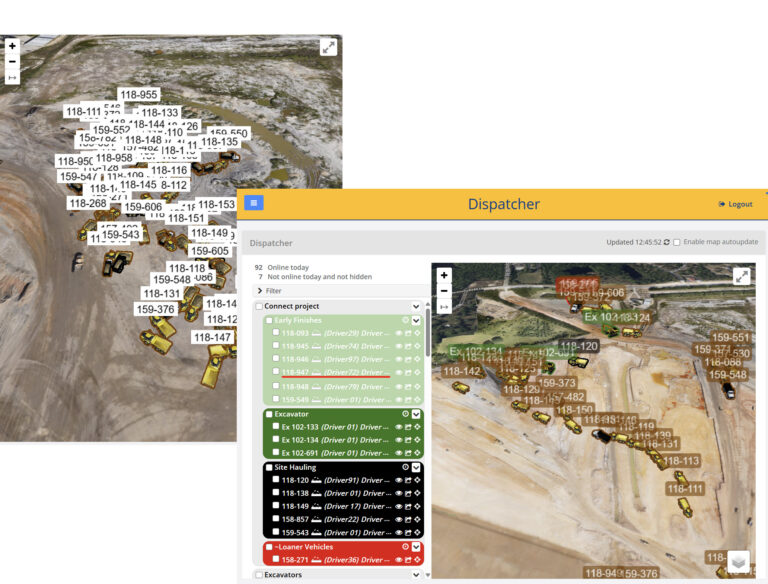

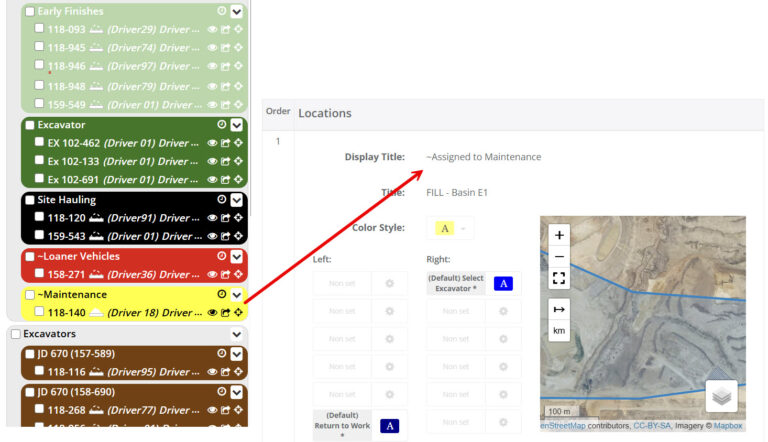

How do you manage your fleet without knowing exactly each machine’s assignment?

RPS Tracker makes it easy to:

All worksite activity is associated with the task; enabling RPS Tracker to report statistics by Task Assignment automatically.

RPS Tracker’s in-cab Smart Data Collectors (SDCs) are rugged, OEM-agnostic, and start capturing data the moment your machine powers on.

Compatible with any fleet. Whether owned, leased, or subcontracted….and across all makes, models, and years.

Installs in 10–15 minutes and stays firmly in place with a tab-tite composite holder and RAM® Twist-Lock™ dual suction cup mount for maximum stability.

Automatic software updates keep your system current with zero downtime.

RPS Tracker’s wireless material placement sensor features a robust, heavy-duty magnetic mount, allowing for quick and hassle-free installation and removal in just 2 minutes. No tools or complex setup required.